EPS Styrofoam Densifiers vs. EPS Compactors

Densifier...compactor…if you work in an industry that generates a great deal of EPS foam scrap, you’ve probably heard both terms being thrown around quite often. One thing you probably do know is that these machines can condense scrap EPS packaging blocks and boxes at an optimal volume reduction ratio.

Many manufacturers of EPS melting machines refer to their equipment as EPS densifiers or thermal densifiers. It seems like many manufacturers of EPS cold compression systems with screw augers refer to them as EPS compactors. Companies that sell hydraulically driven systems tend to call them densifiers or compactors. In the end, all three types of systems — screw, hydraulic or thermal — reduce lightweight foam materials into dense logs, bricks, patties or ropes. All three types of machinery are capable of densifying and compressing a variety of materials.

Understanding Densifier Machine Options

We briefly mentioned a few types of compression systems above. Now, let’s take a deeper dive into screw, hydraulic and thermal densifiers.

Screw-Type Densifiers

Screw-type densifiers work when you need to compact foam that has one consistent density. This type of machine uses augers to push foam through at different speeds and amounts of pressure based on how much foam needs to be processed. These machines will compact the foam into solid logs or blocks.

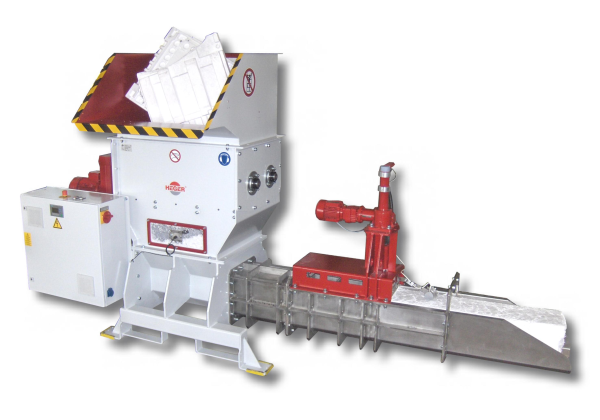

With screw-type EPS densifiers, like the Heger Lion, you can efficiently densify multiple varieties of foam materials with one system. The Lion utilizes cold compression to densify foam with screw-auger technology. This promotes energy-efficiency. With this type of system, external heaters will melt the exterior of the compacted log of any non-binding materials to encase them for easy handling and storage.

Hydraulic Foam Densifier Machines

These machines don’t require the use of heat during the compaction process. That means you don’t have to worry about chemical smells or smoke. Hydraulic densifiers rely on hydraulic pressure to compress the foam and break down its elasticity. These foam densifier machines are capable of processing foams with various densities all at once.

Thermal Densifiers

Thermal densifiers bring the heat — literally. These EPS densifiers do exactly what their names imply. They use heat to melt down foam so it can be extruded and put into containers. These densifiers can also handle multiple types of EPS foams at once.

What Sets Compactors Apart From Densifiers?

Let’s get back to the million-dollar question. What’s the difference between compactors and densifiers? You might be under the impression that they’re two totally different things when it comes to EPS recycling. But to us, it’s all just semantics! These terms tend to be used interchangeably. So, in order to make sure that you get the right equipment for your company, just look for the machine that can handle the foam scrap you have in a manner that lines up with your recycling objectives.

The Advantages of Using a Heger Screw Compactor

Foam Equipment & Consulting knows that our customers need foam recycling solutions that are highly effective and super-efficient. That’s why we are proud to offer Heger screw compactors. Heger EPS recycling screw compactors were designed for long service lives and low maintenance. They can also help your business save on transport and disposal costs for your company.

On top of the few reasons we just mentioned, Heger screw compactors offer some other advantages when compared to thermal and hydraulic densifiers. Here are some of the disadvantages for working with thermal and hydraulic densifiers.

The Drawbacks of Thermal (Melting) Compactors

With thermal densifier systems, contamination and moisture are more likely to affect processing. These melting systems tend to use a lot of energy in comparison to a screw style compacting system when processing expandable polystyrene. Thermal compactors also require a warm-up time that delays processing. However, screw compactor systems can start processing EPS immediately.

Melting compacting systems need plenty of ventilation. Because these systems melt and even burn the material, the fumes they produce must be ventilated. Screw compactor systems don’t require ventilation because nothing is being melted and there are no inhalation concerns.

Disadvantages of Hydraulic EPS Densifiers

Hydraulic densifier machines can be prone to leakage and higher maintenance because of hydraulic valve failure. Heger’s screw compactor system is designed with only electrical drive equipment meaning no hydraulic parts are used. That’s not to suggest that all screw compactors are made without hydraulic components. Some screw press compactors use hydraulics to control the pressure flap density of the logs they produce, which can mean higher maintenance when compared to a Heger system.

Why You Can Rely On a Heger Screw Compactor

Heger is the leader in foam densification through screw press machine design. The company has managed to overcome the limitations that exist with many screw compactors. Heger systems are built robust as well as technically efficient.

Heger screw compactors utilize electrically driven, automatic density controls to adjust pressure to ensure homogeneous density of compressed material. Heger systems are also easy to use even without prior knowledge of the equipment. Heger screw compactors can produce high-density compressed logs of EPS and other materials with a low level of energy expenditure. And thanks to Heger’s high-quality components, their compaction systems require minimal scheduled maintenance and are known for having long service lives.

Find a Foam Densifier Machine that Meets Your Needs

Foam Equipment & Consulting Co. is proud to be a stateside supplier of XPS, EPE, EPP and EPS densifier machines and equipment. Since 1989, we’ve been helping to connect a wide variety of industries with the solutions they need to streamline operations and make them even more profitable. With more than 100 years of expandable foam molding experience, you can trust our industry reputation, product expertise and quality services designed to help your business thrive.

If you have questions about our selection of Heger foam recycling compacting systems or our company in general, reach out to us today. We look forward to helping you.