Crocodile 200

- Throughput per hour: 1 – 2 m³ (35 – 70 ft³)

- Max. volume of individual part size: 0.33 liter (12 ounces or softball sized)

- Achievable Residual Liquid Content: 10 – 30 %

- Discharge Tube Dimension: 210 x 210 mm (8.3” x 8.3”)

Crocodile 250

- Throughput per hour: 3 – 5 m³ (105 – 175 ft³)

- Max volume of individual parts size: 1.0 liter (35 ounces)

- Achievable Residual Liquid Content: 10 – 30 %

- Discharge Tube Dimension: 290 x 290 mm (11.4” x 11.4”)

Crocodile 300

- Throughput per hour: 4 – 8 m³ (140 – 280 ft³)

- Max volume of individual parts size: 1.5 liter (53 ounces)

- Achievable Residual Liquid Content: 10 – 30 %

- Discharge Tube Dimension: 320 x 320 mm (12.5” x 12.5”)

Crocodile 400

- Throughput per hour: 5 – 10 m³ (175 – 350 ft³)

- Maximum volume of individual parts size: 2.5 liter (88 ounces)

- Achievable Residual Liquid Content: 10 – 30 %

- Discharge Tube Dimension: 400 x 400 mm (15.7” x 15.7”)

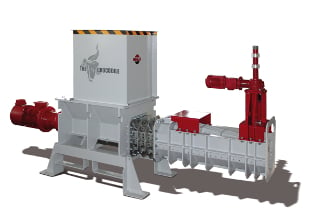

Heger Crocodile

The Heger Crocodile series compactor is designed for the separation of fluids from waste material and compaction of the remaining solids. The Crocodile has been used to remove liquid content from industrial sludge, paper fiber, and mixed waste containers. Depackaging applications include PET beverage containers, aluminum beverage cans, oil bottles, Tetrapaks and aluminum and tin canned foods.

A performance oriented machine concept with robust engineering and drive design technology. The Crocodile System delivershigh output, energy efficient processing while also offering minimal maintenance requirements. The Crocodile System is available in various sizes depending upon the specific processing needs.

Something Powerful

Tell The Reader More

The headline and subheader tells us what you're offering, and the form header closes the deal. Over here you can explain why your offer is so great it's worth filling out a form for.

Remember:

- Bullets are great

- For spelling out benefits and

- Turning visitors into leads.