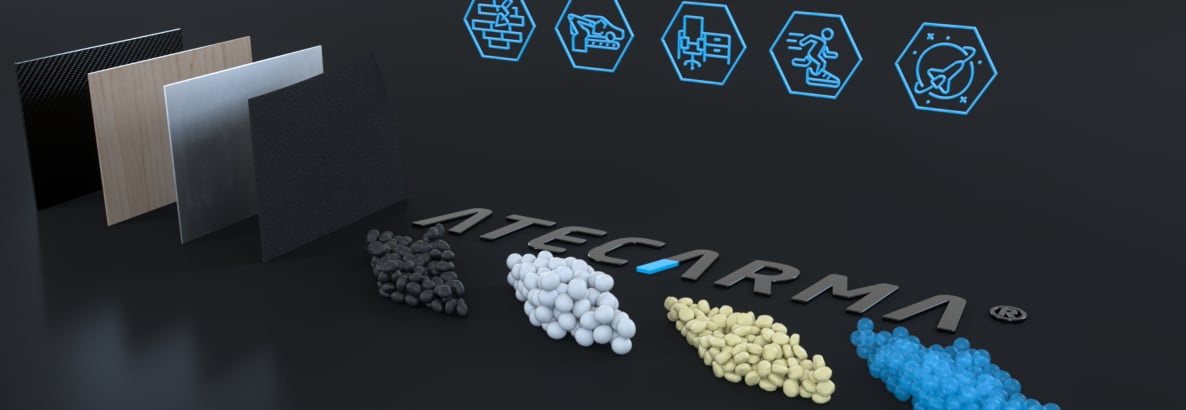

The ATECARMA® Process

Teubert’s new ATECARMA® process allows you to manufacture particle foam and hybrid parts using bead foams, fabric, metal, plastic, wood and more without the use of steam or water. The following is a high-level look at the process of creating particle foam using resource-efficient ATECARMA® production equipment.