Construction Uses for Expanded Polystyrene and Styrofoam Building Materials

Sustainable home construction has put a new emphasis on expanded polystyrene or EPS insulated homes. The demand for more energy-efficient, sustainable homes has led to greater construction innovations, including improved insulation techniques using expandable polystyrene. Insulated concrete forms, or ICFs, and structural insulated panels have become the 21st century’s answer to traditional building methods. New building materials have improved insulation, provided a model for less waste and promoted sustainability in the building industry.

How Insulated Concrete Forms (ICFS) are Changing Construction

Insulated concrete forms have replaced a lot of traditional construction materials. What are ICFs? ICFs are permanent, premade building forms that fit together. They’re laced with rebar and then filled with concrete. Because the forms are insulated on the inside and the outside, they provide a higher level of wall insulation. From sub-level to multi-floored buildings, ICFs help make buildings energy-efficient, greatly improve sound absorption and increase the overall stability and protection from nature’s destructive forces.

Structural Insulated Panels and Their Advantages

Using structural insulated panels, or SIPs, is another efficient design practice for energy savings. SIPs are high-performance building systems often used in residential and light commercial construction. The panels involved are made up of an insulating foam core between two structural facings like oriented strand board (OSB). SIPs deliver the efficiency, strength, and insulation qualities that surpass those of traditional home building practices.

Homes built with SIPs not only deliver superior insulation protection compared to traditional homes, but the strength of them compared to traditional buildings is greater and not as much timber is needed.

SIPs paneling in homes provides better outside noise reduction and noticeably more strength from natural elements than traditional home building materials. SIPs paneling also can save homeowners a great deal. Comparable in pricing to traditional materials, the value of using SIPs is apparent years after construction. It’s been reported that homeowners can save more than 50% on energy costs compared to traditional wood-framed homes.

Other Ways Expanded Polystyrene is Used in Construction

The transportation industry uses expanded polystyrene in a variety of applications. Roads, bridges, embankments all have it as backfill, structural foundation, and even sub-terrain insulation. Utilizing light, non-biodegradable materials to stabilize soft-ground for roadways is particularly popular. The use of expanded polystyrene block does not require heavy land-moving equipment. They can be used both with a natural embankment and/or can be utilized behind retaining walls to reduce the load. This foam also retains stabilization more effectively than soil and other fill alternatives.

Want to Recycle Expanded Polystyrene Used in Construction? Foam Equipment & Consulting Co. Can Help!

The use of expanded polystyrene for construction practices is vast and revolutionizing many aspects of business and sustainability in many industries. Expandable polystyrene can be utilized to reduce our energy consumption and to create opportunities that provide real-world solutions to traditional practices in construction and resource management.

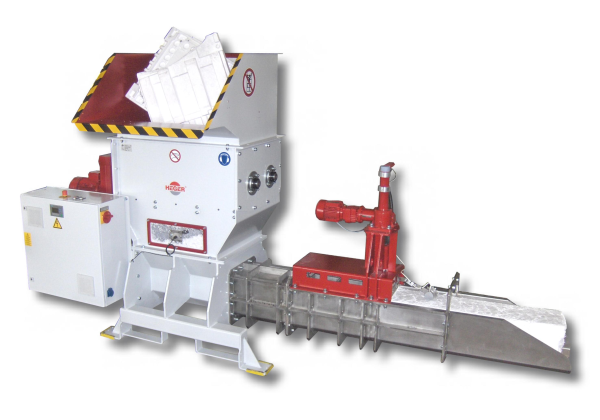

While it’s good to use, it’s even better to recycle EPS foam for sustainability’s sake. Foam Equipment & Consulting has foam recycling solutions that can help you. We offer state-of-the-art EPS foam compactors and compression lines from Heger that can help your organization save on transport or disposal costs. To learn more about our solutions for recycling expanded polystyrene used in construction, reach out to us today!