When faced with the challenges of dealing with foam scrap, specialized foam compacting solutions will provide beneficial waste management and foam recycling options. Whether dealing with expandable polystyrene (EPS), Styrofoam™, extruded polystyrene (XPS) or polyurethane (PUR) foam parts; a quality foam compacting system can reduce the volume of waste up to 97%. This processing of foam waste will minimize or eliminate costs by reducing the frequency of waste services and maximizing transport weight of the materials to a waste processor or foam recycling program!

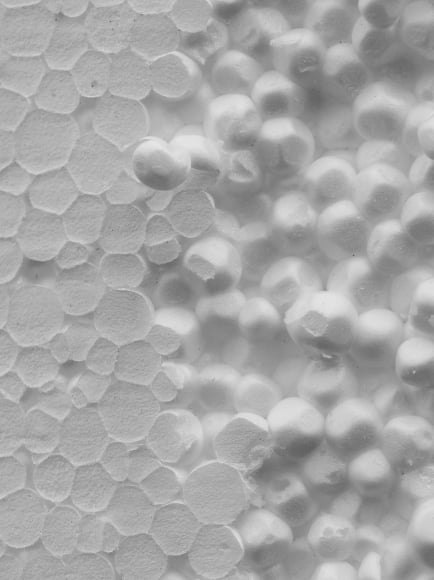

Expandable polystyrene consists of air trapped in a thin layer of polystyrene plastic forming the beads that are bonded to make EPS foam parts. While EPS foam products are great for insulation of buildings and protection of goods, the foam shapes can be bulky and fill waste containers quickly. EPS or Expandable polystyrene is a recyclable plastic. The cold compression foam densifier system efficiently converts EPS waste into high-density logs, reducing or eliminating the costs associated with landfilling of the material. EPS is highly valued as a recyclable plastic, in compressed form, the material can be moved efficiently for recycling.

Styrofoam™ or extruded polystyrene (XPS) is another form of polystyrene foam. This material is mainly used for insulation applications as well as some food service products. Volume reduction using an efficient foam densifying machine will reduce associated waste expense while also providing potential recycling options.

Many forms of polyurethane foam exist on the market for a variety of purposes such as thermal insulation, packaging, and sound insulation. While some PUR materials can be re-used in certain markets, much of the waste PUR product reaches landfills. In this case maximizing the waste container weight with a quality foam compactor may be the best option to reduce waste costs.

Heger Tiger Foam Compacting Systems provide extremely reduced volume of foam waste for maximizing storage and hauling. The Heger Tiger screw press system continuously densifies foam materials into compressed logs for ease in handling and pallet stacking. Due to the completely electrical design and sturdy structure, each system is built for optimal performance and lasting service while requiring minimal maintenance periods.

Whether the operations demand small or large foam recycling equipment, the Heger Tiger Foam Compactor features various models that offer tremendous performance. All Heger design configurations incorporate the utmost in operator safety, whether the high output Tiger 400 EPS Compactor or the smaller Tiger 130 foam recycling machine.

The Heger Tiger machine concept adds custom design options that include optional prebreaker sizes, variable speed drives, extended stabilizing tubes, optional feed conveyors and large fabric buffer silos. Additionally, each system comes with the following features:

The Heger Tiger T Series Foam Compactors utilize an innovative machine concept providing efficient processing of EPS and XPS foam materials. The Heger Tiger T series grinds and compresses foam parts with a dual-function screw drive. The screw drive, equipped with breaker teeth, will break-down foam parts while conveying the material into the compression channel. The Tiger T series foam densifier is a space-saving design, while still providing the utmost in performance during the foam compacting operation.

Tiger 130 T

up to 33 lbs. hourly

block dimensions

130 x 130 mm

Tiger 200 T

up to 132 lbs. hourly

block dimensions

210 x 210 mm

Tiger 300 T

up to 265 lbs. hourly

block dimensions

320 x 320 mm

Tiger 400 T

up to 550 lbs. hourly

block dimensions

400 x 400 mm

The Heger Tiger B Series Foam Compacting machine is robustly designed pairing an efficient prebreaker or grinding system with the Tiger screw press foam densifier. The addition of a prebreaker to the foam compactor system provides more flexibility while allowing the screw press to concentrate all efforts to the compression process. Conveyor feed options are possible adding efficiency and safety for operators during the foam recycling operation. The prebreaker allows for large, thick foam shapes to be processed quickly and efficiently.

Tiger 130 B

up to 33 lbs. hourly

block dimensions

130 x 130 mm

Tiger 200 B

up to 132 lbs. hourly

block dimensions

210 x 210 mm

Tiger 300 B

up to 265 lbs. hourly

block dimensions

320 x 320 mm

Tiger 400 B

up to 550 lbs. hourly

block dimensions

400 x 400 mm

Tiger 2x400 B

up to 1100 lbs. hourly

block dimensions

400 x 400 mm

Tiger 3x400 B

up to 1650 lbs. hourly

block dimensions

400 x 400 mm

Foam Equipment & Consulting Co.

4173 Shoreline Drive

Earth City, Missouri 63045-1217

314-427-4395

8am-5pm CDT