When faced with the challenges of dealing with foam waste, specialized foam compacting solutions will provide beneficial waste management and foam recycling options. Whether dealing with polyethylene foam or polypropylene foam scrap issues; a quality foam compacting system will reduce the volume of the foam parts. This compression process of foam parts will minimize or eliminate costs, by reducing the frequency of waste removal services, as well as maximizing transport weight of the materials to a processor for recycling!

Polyethylene or LDPE foam is widely used as a packaging material due to its impact absorption properties as well as its flexibility. Polyethylene foam can be found in a wide range of densities proving useful for various applications. Normally extruded, polyethylene foam can be found in many colors. Polyethylene foam can be molded in bead form like EPS and EPP foam products. PE fabricators, recycling operations, and commercial or retail facilities can achieve reduced waste costs and even foam recycling programs by operating a polyethylene compacting system such as the Heger Lion.

Polypropylene foam has great impact absorption qualities as well as shape retention. Polypropylene foam is used in automotive applications as well as packaging. Primarily used in the automotive industry as impact absorption in many areas of vehicles, and EPP foam parts are also used as dunnage or packaging for various auto components. There is great opportunity to economically recycle polypropylene foam parts utilizing the Heger Lion foam densifier. The foam compression system compacts the EPP foam parts for maximizing transport hauling weight. An EPP foam recycling operation will reduce or eliminate costs associated with waste hauling.

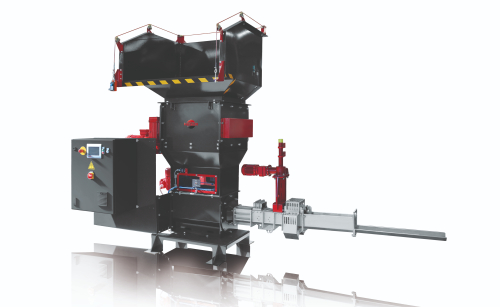

The Heger Lion Foam Compacting System is designed for processing multiple foam material types for foam recycling operations. A cold-compression foam densifier, the Lion System significantly reduces the volume by up to 97%, increasing density of foam materials through screw-auger compression technology. The robust engineering and design allow the Lion foam compactor to effectively compress foam plastics such as polyethylene and polypropylene into high-density logs. Unlike expanded polystyrene or EPS, polyethylene foam and polypropylene foam are more resilient and do not bond together after screw compression. The addition of the external heaters melt only the exterior sides of the compressed foam log, encasing the compressed foam, ensuring easy handling, stacking, and storage for foam recycling operations.

While offering multiple programming options for each material type, the sophisticated software and touch-screen PLC of the Heger Lion foam densifier provides real-time monitoring of the complete machine operation.

The Heger Lion System is one of the most advanced foam compression systems on the market, maximizing service life and operational value. Designed to meet individual project needs, the Heger Lion is also available with the following optional features:

Lion 130 B

up to 33 lbs. hourly

block dimensions

130 x 130 mm

Lion 200 B

up to 132 lbs. hourly

block dimensions

210 x 210 mm

Lion 300 B

up to 265 lbs. hourly

block dimensions

320 x 320 mm

Lion 400 B

up to 550 lbs. hourly

block dimensions

400 x 400 mm

Lion 2x400 B

up to 1100 lbs. hourly

block dimensions

400 x 400 mm

Foam Equipment & Consulting Co.

4173 Shoreline Drive

Earth City, Missouri 63045-1217

314-427-4395

8am-5pm CDT